The Defense Threat Reduction Agency’s Chemical and Biological Technologies Department is developing materials to provide ‘second skin’ protection from exposure to chemical and biological agents with the breathability and comfort of warfighters’ own skin.

To mitigate shortcomings of current PPE, DTRA’s Dynamic Multifunctional Materials for a Second Skin (DMMSS) program is exploring three different approaches which aim to develop technology for switchable membrane systems. More specifically, these membranes will close their pores in response to chemical agents and remain open when not exposed.

Second Skin materials utilize chemistry that has been synthesized onto membranes that respond to chemical agents by reducing or eliminating penetration before reaching the skin. This new, state-of-the-art technology will allow breathable fabric uniform that can transition into a protective garment if a threat is present.

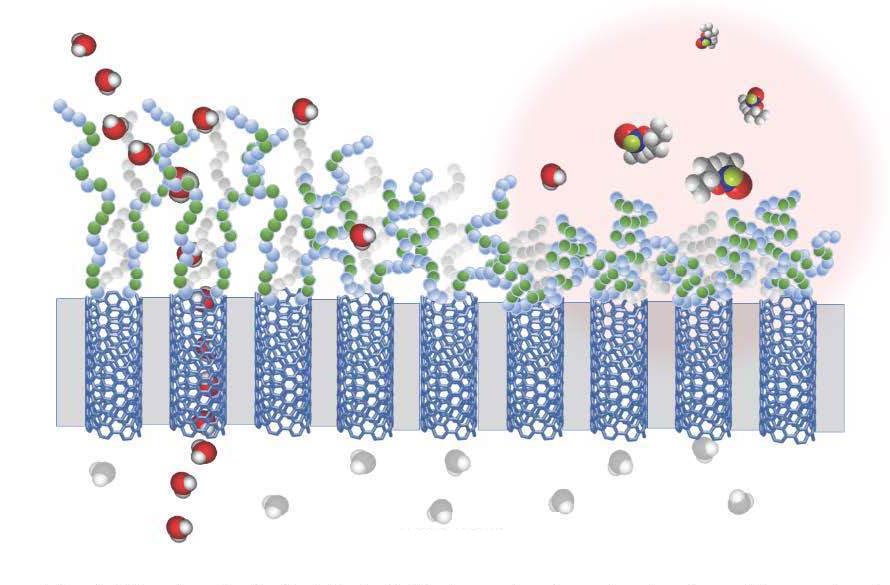

Carbon Nanotubes Embedded in Membranes

The first approach utilizes aligned carbon nanotubes (CNT) embedded in membranes. The nanotubes have small diameters which allow water and other vapors through, but blocks biological agents. This approach also utilizes responsive polymers that collapse and block the CNT pores when exposed to chemical agents. Fabrication of this membrane has now increased from one centimeter to four inches in the process of increasing coverage areas.

Enzyme Embedded Copolymer Membrane

The second approach involves developing an enzyme embedded copolymer membrane. When exposed to chemical agents, these membranes expand and close from an enzyme reaction with the chemical agent, protecting warfighters wearing the garment. This technique produces membranes with uniform pore sizes and minimal defects, creating a more reliable product. The DMMSS program has begun roll-to-roll development, creating samples up to eight inches wide.

Coating Fabrics with Electrically Conductive Materials

A third approach utilizes electrically conductive materials that are coated onto existing fabrics. This coating responds when exposed to a small electrical current, which closes the fabric from penetration. The pores close in mere seconds, creating a protective state that can last up to 24 hours. Another current can either open the membrane or maintain the protective state. This coating has been demonstrated on carbonized textiles.

As the toxic threat constantly evolves, warfighters rely on PPE that can adapt at the speed of relevancy from hostile enemies to viruses and volatile chemicals. The DMMSS program offers an integrated, layered defense through engineering and integrating material solutions for warfighters.

Source: DTRA’s Chemical and Biological Technologies Department, adapted.

Image: Schematic representation of a CNT membrane functionalized with chemical-threat-responsive polymers. In a safe environment the responsive polymer chains are extended and the material allows rapid transport of water vapor; in a contaminated environment the polymer chains collapse upon contact with a chemical threat, block the CNT pores and prevent the passage of the threat across the membrane. The CNT pores are small enough to sieve out biological threats in both configurations of the polymer chains. Credit: DTRA