High-purity depleted uranium is an important strategic material for ongoing and planned modernizations of the U.S. nuclear weapons stockpile. However, according to National Nuclear Security Administration (NNSA) estimates, the nation has a very limited supply of depleted uranium feedstock, and its current supply of depleted uranium metal will be exhausted in the late 2020s. NNSA also does not have the full range of capabilities needed to manufacture depleted uranium into weapon components needed for modernizing the stockpile.

A new Government Accountability Office report to the U.S. Senate Committee on Armed Services examines NNSA’s management of depleted for nuclear stockpile modernization, their efforts to obtain the necessary quantities of depleted uranium to meet stockpile modernization requirements; the status of NNSA efforts to develop modernization component manufacturing capacity; and the extent to which NNSA is cohesively managing the depleted uranium program.

GAO reviewed relevant agency documents; interviewed NNSA officials and contractor representatives; and conducted site visits at headquarters and at research, development, and production locations.

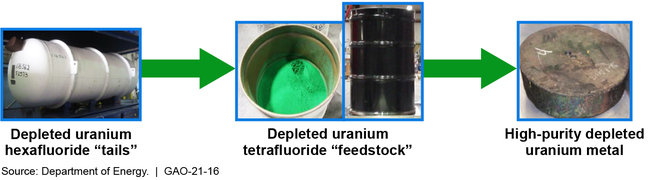

To reestablish a supply high-purity depleted uranium, NNSA plans to install conversion equipment in an existing facility at DOE’s Portsmouth site in Ohio. DOE initially estimated costs of $12 million to $18 million to design and install the equipment, according to the GAO report, with operations beginning in fiscal year 2022. However, in March 2020, NNSA requested an increase in conversion capacity, and an updated proposal in July 2020 estimated costs of $38 million to $48 million and a slight delay to the start of operations. NNSA plans to convert the feedstock into depleted uranium metal using a commercial vendor at a cost of about $27 million annually.

NNSA is also taking steps to reestablish and modernize depleted uranium component manufacturing capabilities, but it risks delays that could affect the timelines of nuclear stockpile modernization programs, according to officials, GAO found. NNSA has reestablished processes for manufacturing some depleted uranium components but not for components made with a depleted uranium-niobium alloy, a material for which NNSA has no alternative. Thus, restarting the alloying process—a complicated, resource-intensive process that has not been done in over a decade—is NNSA’s top priority for depleted uranium and presents a very high risk to timely supply of components for certain nuclear stockpile modernization programs, according to NNSA documents and officials.

NNSA is also developing more efficient manufacturing technologies, in part because the current alloyed component process wastes a very high percentage of the materials and NNSA cannot recycle the waste. For its depleted uranium activities, NNSA has requested an increase in funding from about $61 million in fiscal year 2020 to about $131 million in fiscal year 2021.

NNSA officials said that they are gathering cost data from the piecemeal data NNSA has already collected from existing projects, but they do not yet have sufficiently comprehensive data to deploy a full–scale life-cycle cost estimate for the DU scope of work. According to NNSA officials, it is premature to develop a lifecycle cost estimate for the new depleted uranium modernization program; they intend to do so once the scope and schedule are further developed.

Until recently, GAO notes that NNSA had not managed depleted uranium activities as a coherent program in a manner fully consistent with NNSA program management policies. Since October 2019, however, NNSA has taken actions to improve program management. For example, NNSA has consolidated management and funding sources for depleted uranium activities under a new office and Depleted Uranium Modernization program with the goal of better coordinating across the nuclear security enterprise. Further, NNSA appointed two dedicated Federal Program Managers to gather and organize information for required program management and planning documents.